Production is coming back from Asia. Responsibility for the environment as well.

Today's people want untouched nature, a high standard of living, a warm room, a smartphone, a personal car and a four-lane highway at the same time. Unfortunately, we have to take into account that every human activity has its own impact on the environment and you cannot get everything good at once.

The industrial revolution has created a situation where in order to produce a product at an affordable price for the consumer, industries have to process large volumes at the most affordable price, which has brought success to Asia in the production of consumer goods. As a result, we have outsourced most of our environmental footprint to third countries, but this will change in the near future.

The pandemic has sharply highlighted supply problems from far-flung regions: Asia, South America and the United States. Currently, however, production is being brought back from Asia to Europe to keep supply chains closer. As a society, we are moving towards sustainable resource use, i.e. the use of local renewable materials.

The environmental footprint becomes visible

This means, among other things, that the environmental footprint of our consumption returns home and becomes visible to the eye. In the light of the climate goals, we are starting to take responsibility for the environmental effects of our activities and also take into account the fact that consumption is becoming more and more expensive. And it becomes significantly more expensive for those who make the green transition headlong, without thinking and researching today's technological possibilities and resisting the sole desire to ensure a smooth and as painless as possible transition for society.

The last year has shown that the manufacturing industry keeps the economy afloat in difficult times. According to economists, the balanced development of the economy requires the addition of capital-intensive companies that use complex technology.

A recently completed study of the socio-economic impact of the forest and timber industry shows that the on-site processing of currently exported pulpwood would provide the Estonian economy with additional added value in the hundreds of millions of euros and create almost 7,000 new jobs. The investment to build a competitive wood chemical plant is high and has a long payback period, but if we miss this global train, there is much more to lose in the future.

Jan Kers. Photo: Sven Arbet

An expensive but worthwhile option

Estonia is already at the top of the world in mechanical wood processing, but different assortments are created when the forest is cut down. It is not possible to make building materials from crooked trees and branches, but there is a great potential for consumer plastics, clothing, packaging and finishing materials that we have produced from fossil raw materials until now. This is possible with the help of chemical beneficiation of biomass and industrial biotechnology, for the creation of which in Estonia we need a new level of scientific development and innovation capabilities.

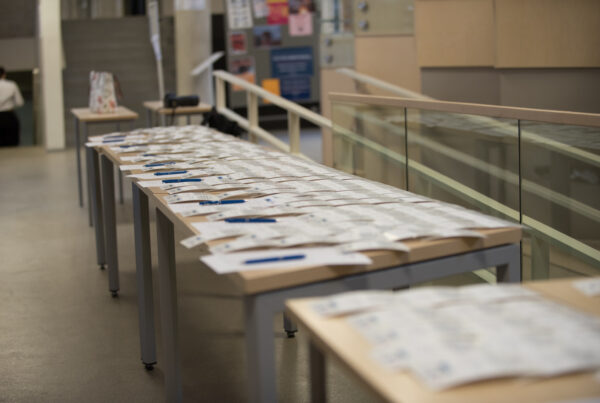

After the wooden house is demolished, the wood can be used to make, for example, vintage furniture, pallets and packaging. Kraft paper bags can be shredded, reprocessed and the cellulose fiber contained in them can be recycled to make paper, packaging or chemical products. In the last step, paper bags are compostable if they are not covered with a plastic coating or laminated film.

Therefore, it would be necessary to encourage cooperative and interdisciplinary research and development activities in the fields of bioeconomy. Also consortium-based applied research and development work in universities and business. From the experience of the Nordic countries, we see that clusters of science-based entrepreneurship gather around wood refineries, which deal with the development and improvement of new technologies in order to develop new bioproducts.

The basis of this development is, among other things, Estonian paperwood, which today is used in Finland and Sweden instead. Why are we willing to be a pantry for Scandinavian wood refineries, instead of chemically depreciating renewable raw materials ourselves, creating value for the Estonian economy and jobs for Estonian people?

It is worth remembering that it is only possible to get on the biocircular economy train in close cooperation between researchers and companies. An important prerequisite is the corresponding state support, i.e. the creation of favorable conditions with the government's policy. Bio-resources play a very important role in the so-called clean economy, and their use opens up many new opportunities for the development of local industry in industrial fields that did not exist in the country until now. The highest possible high-tech enhancement of Estonian wood is one of our opportunities to carry out a milder green transition.

Superficial opposition

There is strong opposition to any major project among certain interest groups. Every opportunity is often used to start collecting signatures and make news about how an entire community is against something. Activists are mobilized by buses to wherever they are needed, and protests begin even before scientific research takes place or meaningful discussion begins.

On the one hand, this reaction is understandable - people are concerned about the environment, and this has made many anxious to act for a better environment. But in order to fulfill the goals of the Green Deal, public debates should be taken deeper in content than superficial overreaction.